January 2024 Good Tech News

This article is from our Good Tech News Newsletter - covering some of the best tech that furthers humanity.

This Technology Education Collaborative newsletter covers some of the best tech that furthers humanity. We know it’s easy to get pessimistic in today’s technology landscape. This newsletter serves as a reminder of why humans still love tech anyway. After all, so much of today’s newest technology is amazing, awe-inspiring, and often, just plain fun.

Spinal Implant Helps Man with Parkinson’s Disease Walk Again

Thanks to a revolutionary spinal implant, Marc Gautier, 62, enjoys Sunday strolls around a pond despite his advanced Parkinson’s disease. Parkinson’s disease, for which there is currently no cure, causes increasingly severe mobility issues due to a lack of dopamine in the body.

Using neuroprosthesis to treat Parkinson’s isn’t new. In addition to medications that help alleviate symptoms, treatment can include implanting electrodes in a person’s brain to produce electrical activity that helps movement.

However, that treatment eventually wears off over time as the disease progresses.

In this case, Swiss, Spanish and French researchers shifted their focus from the brain to the spinal cord. The implant stimulates leg fibers in Gautier’s legs that have weakened as a result of disease. Even more neat, Gautier can turn the stimulation on and off by himself (he turns it off when he’s sitting down for long periods or sleeping).

Though it took several weeks of rehabilitation for Gautier to be able to walk normally again, the improvement was immediately noticeable.

Still, researchers caution more testing is needed and commercial viability could be up to 10 years away.

All the same, it’s certainly a step in the right direction. Just ask Gautier.

Phoenix Tests Using AI to Monitor Wastewater

Thanks to artificial intelligence, Phoenix may be able to discover polluters who illegally dump toxins into the city’s sewage system in near real time.

The city launched a six-month test pilot that uses sensors to transmit data about wastewater to an intelligence platform designed by Kando Pulse, an Israeli-based AI company.

The sensors alert workers to irregularities in Phoenix’s wastewater. Detectable issues can range from dangerous PH levels to irregular temperature. Those changes frequently occur when solvents, oils or other substances harmful to sewer pipes are dumped down the drain. The resulting water issues take time to detect, which increases how far the damage spreads. It also makes it harder for authorities to identify who dumped the chemicals.

With the Kando sensors, however, changes can be detected and, in some cases, traced back to the source in near real-time, long before the contaminated water gets to the water treatment plant. That means less damage to the wastewater system overall and less time and money spent on repairs.

The current test pilot uses 16 devices installed in various sewer drains throughout the city.

New 3D Printing Method Leads to Flexible Hand Prosthetics

One of the main challenges in leveraging 3D printing and robotics to create usable, realistic prosthetics for certain limbs is the inability to replicate the soft, flexible parts of the human body that enable it to move in specific ways.

This is particularly true when it comes to hands and feet, possibly the most complex structures in the human body. In addition to a large number of very small bones, both appendages a lot of connective tissues, small muscles and ligaments. Giving a thumbs up, or using a curled toe to grip the pen that fell under your desk seem like simple acts but are actually basically biomechanical miracles. They’ve proven hard to replicate due to some of the limitations of traditional 3D printing methods.

But perhaps not for long, as Ars Technica reported in November 2023.

Using a new 3d printing method called vision-controlled jetting (VCJ), a team of researchers from the Swiss Federal Institute of Technology (ETH), Zurich, and a U.S.-based startup called Inkbit, have created a prosthetic hand that has flexible tendon- and ligament-like structures.

In addition to the flexible components that add fluid mobility, the hands were printed in a single session. And, during the printing process, it essentially self-corrected any errors that were made using a scanner.

All of this is solid reason to hope, though its worth noting these results must be replicated outside a lab environment and then somehow become affordable. If you ever wonder why there are some individuals still using mechanical hooks as prosthetics, the reason is almost always cost.

That said, this technology gives rise to the ability for policy and society to catch up with tech and further humanity.

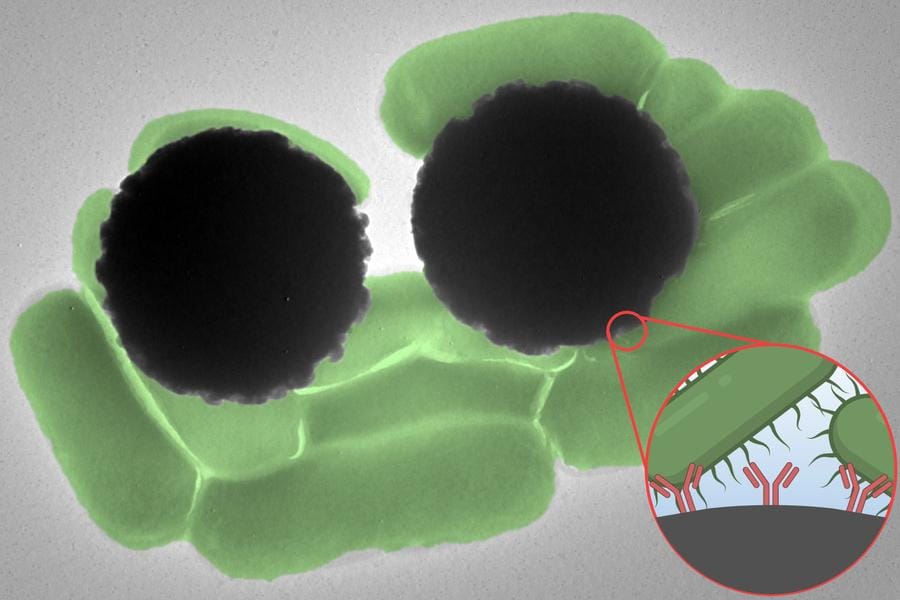

Process to Detect Pathogens in the Body and Food Sped Up with Microscopic Beads

Whether it’s blood test results that can take days or weeks or an outbreak of illness due to contaminated food or water, when it comes to harmful pathogens, every second counts.

A research team at MIT may have found a way to drastically reduce the time it takes to test for pathogens using Dynabeads. These highly magnetic, microscopic beads themselves aren’t new tech, but the way they are being used by researchers is new.

Dynabeads test blood and other items for specific molecules, usually harmful pathogens like Salmonella or sepsis. The beads are coated with antibodies that attach to specific molecules in the test sample. Then the Dynabeads are separated from the test sample using magnets. The molecules that are attached to the beads are then identified or analyzed through another process.

Confirming the specific molecules a tester is looking for have been found, however, adds time and complexity to the testing process.

But researchers who hoped to make testing using Dynabeads both faster and portable thought of a different way to leverage the tech (a fantastic example of how technologists are often creative professionals, too).

One way researchers identify the molecules is by using Raman spectroscopy. Molecules are made of cells and those cells all refract or react to light differently, giving them something like a specific signature.

Initially, researchers thought that light signature might be the key to solving the time and portability problem. But then they noticed the Dynabead themselves had an incredibly strong Ramen signature. By focusing on the beads’ signature, researchers were able to identify the presence of salmonella within half second in a laboratory test.

There’s still a very long way to go from finding Salmonella in a lab test tube to creating a portable system that can identify a human case of sepsis in a rural or resource-strapped the pasteurization hospital. But there’s now a clear path to do so and, if the pasteurization of milk and the ability to test for multiple sclerosis is any indication, it’s only a matter of time before that portable, faster testing exists.